Galvan is a 5% aluminum galvanized coating plus alkaline alkaline elements that are created on low -carbon and carbon steel wires under a specific process.

Galfan coating increases steel corrosion resistance by up to 3 times compared to pure galvanized (zinc coating).

- Excellent plague

- Very high corrosion resistance

- Having an ideal surface for color and use without cover

- Protect against high heating

| Electro galvanized | Hot-Dipped Galvanized | Galfan | Note: 5 = Best, 1 = Worst |

| 5 | 3 | 5 | Formability |

| 3 | 3 | 4 | Corrosion Resistance (Bare) |

| 5 | 5 | 5 | Sacrificial Protection |

| 3 | 3 | 5 | Corrosion Resistance (Formed) |

| 5 | 4 | 5 | Paint Adhesion |

| 4 | 4 | 5 | Corrosion Resistance (PAINTED) |

Note: Best = 5, the worst = 1

-Construction and structures: partitions, pools, greenhouses, entrance and guard doors, doors frame, structural lattice ceilings

-Agriculture and breeding: As a fence in the fields, bulk products in the fields and vineyards

-Customs: Cables used in oil extraction structures, fishing ropes, thermal and refrigeration installations

Automation: Snow Cars, Automatic Doors, Spring Wires

Frameworks: Chain and hooks

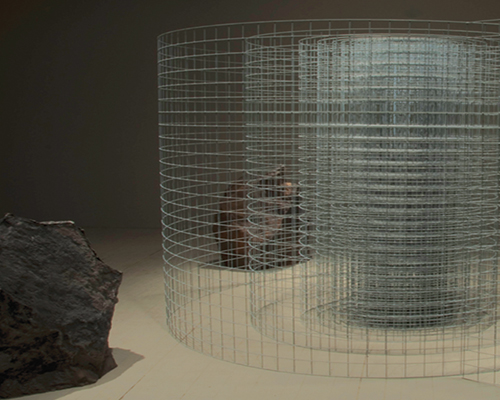

Due to the high corrosion resistance, Galfan products are used to manufacture Gabion.

Carbon Galfan Technical Specifications with a diameter of 6.00-1.00 mm

1-Min. Tensile Strength (MPA):

| HARD (MPA) | Medium (MPA) | Soft (MPA) | Wire Diameter (MM) |

| 820-825 | 485-690 | Max. 515 | 1.00-2.00 |

| 585-795 | 485-655 | Max. 515 | 2.00-2.50 |

| 550-760 | 450-620 | Max. 485 | 2.50-4.70 |

| 515-725 | 415-585 | Max. 485 | 4.70 and above |

3- Galfan cover: Different classes

2- Galfan Coating: Different Classes

| Classc | Class 100 | Class B | Class 60 | Class 3 or a | Class 1 | ASTM A856 |

| – | – | Class e | Class B | Class ab | Class a | BS EN 10244-2 |

Carbon Galfan Technical Specifications with diameter 4.82.27 mm

1-Min. Tensile Strength (MPA):

| ASTM B958 | ASTM B803 | ASTM B802 | Diameter (MM) | ||

| Ultra-High | EXTRA-HIGH | Class C | Class a | ||

| 1965 | 1825 | 1620 | 1310 | 1450 | 1.27-2.28 |

| 1900 | 1790 | 1590 | 1280 | 1410 | 2.29-3.04 |

| 1860 | 1760 | 1550 | 1280 | 1410 | 3.05-3.55 |

| 1825 | 1725 | 1520 | 1240 | 1380 | 3.56-4.82 |

2-Min. Stress at 1% extension (MPA):

| ASTM B958 | ASTM B803 | ASTM B802 | Diameter (MM) | ||

| Ultra-High | EXTRA-HIGH | Class C | Class a | ||

| 1580 | 1550 | 1450 | 1170 | 1310 | 1.27-2.28 |

| 1550 | 1515 | 1410 | 1140 | 1280 | 2.29-3.04 |

| 1515 | 1480 | 1380 | 1100 | 1240 | 3.05-3.55 |

| 1480 | 1450 | 1340 | 1070 | 1170 | 3.56-4.82 |

3. Min. Elongation (%):

| ASTM B958 | ASTM B803 | ASTM B802 | Diameter (MM) | ||

| Ultra-High | EXTRA-HIGH | Class C | Class a | ||

| 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 1.27-2.28 |

| 3.0 | 3.0 | 3.0 | 30 | 3.5 | 2.29-3.04 |

| 3.5 | 3.5 | 3.5 | 3.0 | 4.0 | 3.05-3.55 |

| 3.0 | 3.0 | 3.5 | 4.0 | 4.0 | 3.56-4.82 |